DXF Shape Designer

The DXF shape designer module is essentially a 2 dimensional CAD program that is fully integrated into Glass Office. Below are examples for sealed unit manufacturers and glass processors to give you an idea of the scope of the program. In addition, we have added a toolbar with all of the typical processes that you may want to add to a piece of glass, for example, drilling a hole, cutting out a notch, adding a door patch fitting, etc.

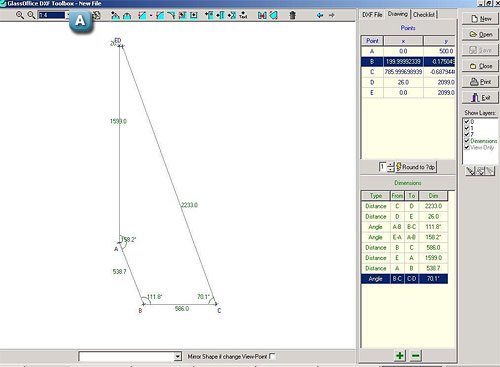

Unit Manufacturers and Tougheners

On this screen we've created a shape that isn't available in any standard shape library and only contains one 90 degree angle (at the top on the 20mm flat). The program can import these DXF files from conservatory roof programs, such as Roofmaker, or you can create them yourself from diagrams sent in by customers. The program already knows the make up of the glass and is aware of which sides of the glass are coated, and will export the size to the glass optimiser, where it can be nested with other pieces from other jobs in the batch. The optimiser will flip pieces where it can, but not if the glass is coated.

Click here to enlarge

A - the tool bar allows the following functions (from left to right)

![]()

• Add a point to a line • Add a bulge to a line • Cut off a corner (as point E below)

• Round off a corner (as point C below) •

Round an internal radius •

Cut out a corner •

Cut out a notch

• Add a circle/hole (and either score a drill centre or scribe the perimeter of the circle - or both) •

Add a line •

Add a pre-defined detail (as point B below) •

Add some text

•

Flip the shape

• Rotate the shape •

Delete the shape • Undo the last few modifications you've made to the shape

Glass Processors

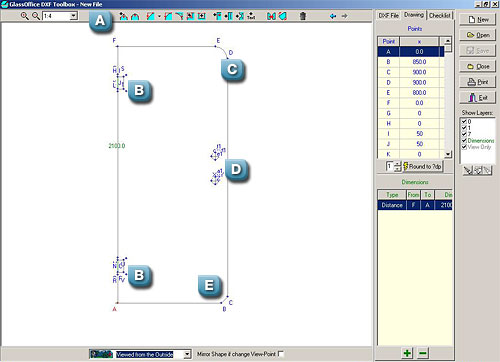

The DXF toolkit is equally useful for glass processors.

Click here to enlarge

A - the tool bar allows the following functions (from left to right)

![]()

• Add a point to a line • Add a bulge to a line • Cut off a corner (as point E below)

• Round off a corner (as point C below) •

Round an internal radius •

Cut out a corner •

Cut out a notch

• Add a circle/hole (and either score a drill centre or scribe the perimeter of the circle - or both) •

Add a line •

Add a pre-defined detail (as point B below) •

Add some text

•

Flip the shape

• Rotate the shape •

Delete the shape • Undo the last few modifications you've made to the shape

B - here we've added a pre-defined shape of a door hinge which comprises of a notch and 2 holes. This is pre-drawn with a CAD program and stored as a standard DXF file, which can then be pulled in and merged with the current DXF. This would typically relate to a standard door hinge that is often used

C - here we've rounded off an existing corner with a radius, this can also be done for internal corners

D - here we've added 2 x 30mm holes, and asked the program to both score the circle and score a 4mm cross for the centre of a drill

E - here we've cut off the corner at a given distance

The resulting DXF can then be optimised, and transferred to CNC cutting equipment.

© 2012 Clear Thinking Software